ARLYN CLOTHING CULTURE LLP

With 50 years of experience in the garment industry we are one of the pioneers in the trade.

Mr. Chander Mahant, founded the business,under the name of Shakuntla’s Exports in 1971 & Shor Shot India Pvt.Ltd. in 1996.

Garment manufacturing and export has been our core business and we are proud to have excelled in the trade

and learn from the same each day.

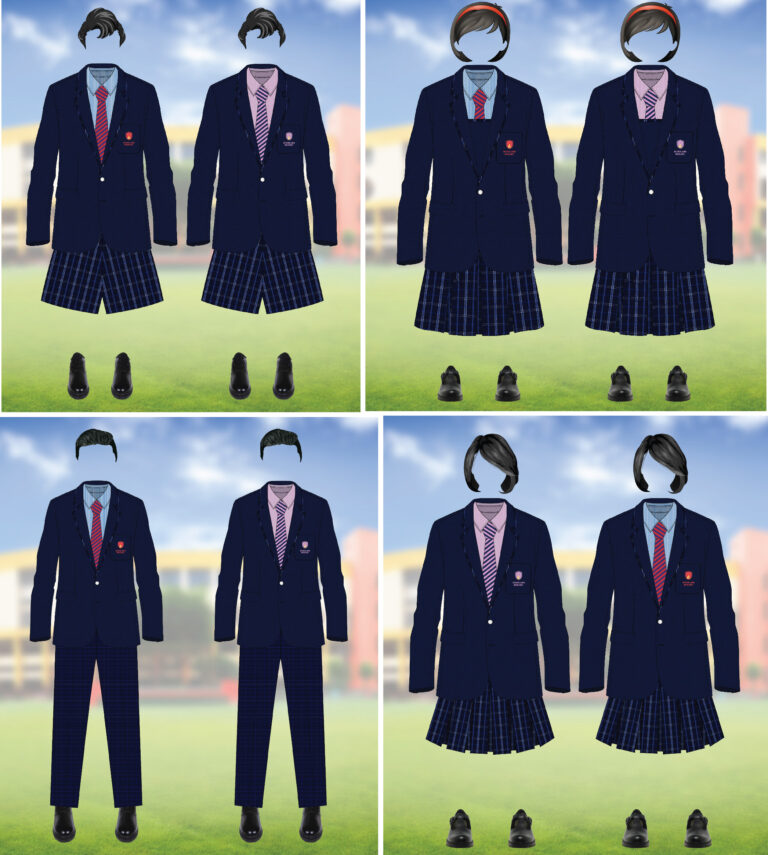

Arlyn Clothing Culture is a new off shoot of the parent companies Shakuntla’s and Shor Shot India Private Limited for uniforms.

It is a company set up to cater to the domestic market, as we have identified the opportunity of growth in lndia.

Located in Noida, we are a company who would like to associate ourselves with the mighty Reliance Industries and their trusted agents Devisahai Charandass Associates get started on the domestic side for uniform manufacturing.

1. Constantly striving to produce newer collections and approach the global & domestic market with fresh designs and high quality garments.

2. Raw material sourcing up to the packaging of final product, a garment’s journey goes through stringent quality checking with the company’s mission to deliver a quality product to it’s end customers.

3. The company has modern machinery to ensure high quality production of woven apparel and we also explore the option of entering non wovens given the demand and requirement.

4. Upgrading our production facilities from time to time to keep up with the modern manufacturing trends and maintain international quality standards.

FABRIC PROCUREMENT :First step in the production process is to procure and quality control the fabric in accordance to the buyer’s needs.

QUALITY CHECKS :At the time of the resource allocation,

checks are carried out to get consistent quality.

CUTTING :The The fabric after being cut is again subjected to rigorous part checks. The fabric is then bundled, numbered and issued to the Assembly Line for stitching.

STITCHING :The department has an inbuilt quality control unit whereby online supervision of stitched garment is carried out to check any possible defects. The garment is then forwarded for buttoning and finishing

QUALITY CHECK PERSONNEL :All ready pieces are inspected which ensure adherence to the specifications given by the buyers.

RECHECKING :The quality check doesn’t end here. Every garment is RECHECKED to further ensure our confidence while sending a shipment.

DISPATCH: After the process of rechecking, the goods are finally moved to the dispatch department.

.